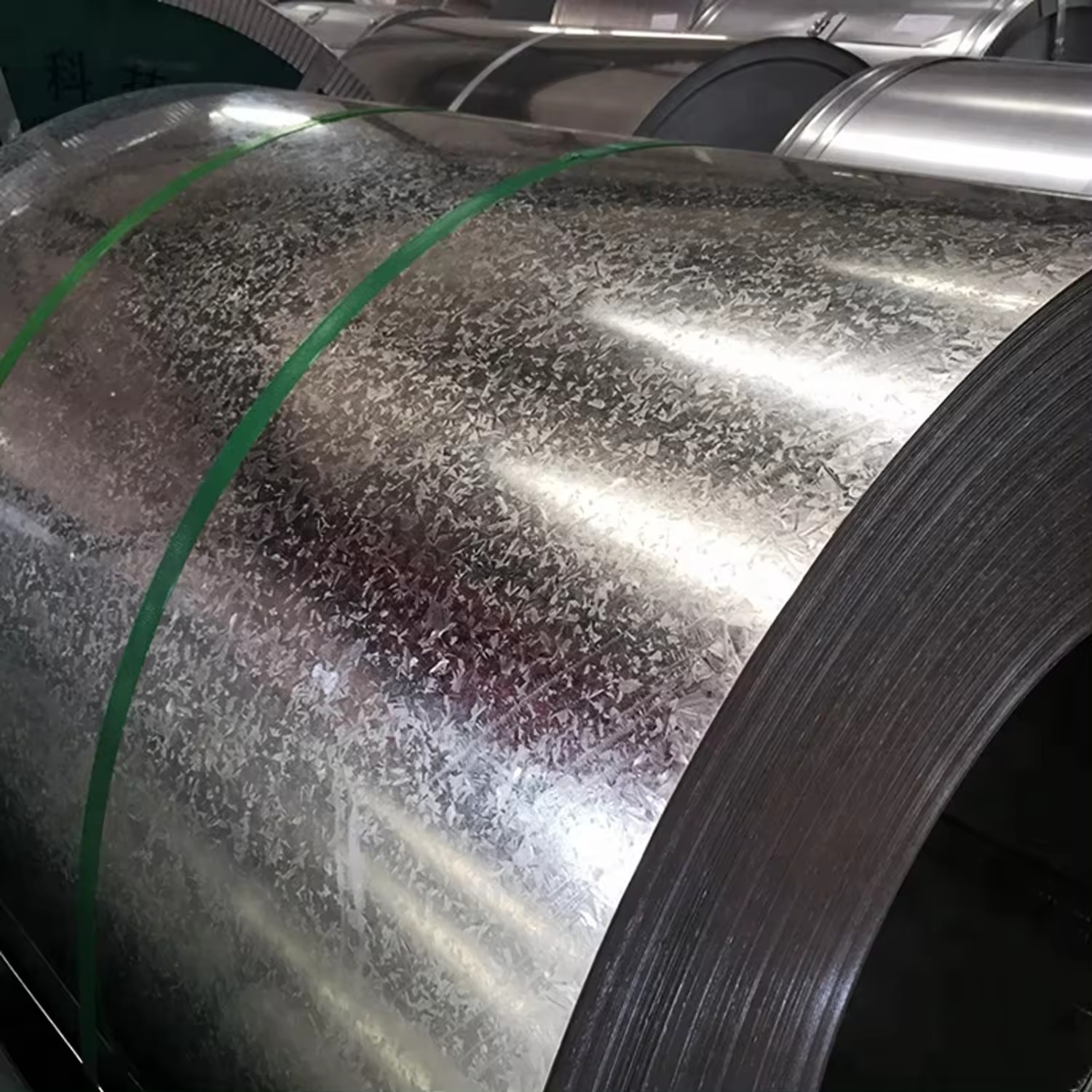

Galvanized Steel

Galvanizing is a metal anti -corrosion method that is to coat zinc on the metal surface to prevent metal from being corroded. Zinc is an active metal that is easily oxidized in the air, forming a dense zinc oxide film. This layer of film can protect the metal from being corroded.

There are many methods for galvanizing, such as electroplating, hot immersion, chemical plating, etc. Among them, electroplating is the most commonly used method. It is to use metal workpieces as cathode, put into the electrolyte containing zinc ions. After power is powered, zinc ions are restored to zinc atoms on the cathode and deposited on the metal surface to form a layer of galvanized galvanized. layer.

The thickness and uniformity of galvanized layers have a great impact on galvanized effects. If the galvanized layer is too thin or uneven, the metal will easily be corroded. Therefore, in the process of galvanizing, the thickness and uniformity of the galvanized layer need to be strictly controlled.

The galvanized layer has good corrosion resistance, abrasion resistance, conductivity and thermal conductivity, so it is widely used in the aspects of anticorrosion, decoration, conductivity and thermal conductivity of metal products. For example, in the anti -corrosion of metal products, galvanized layers can protect the metal from being corroded and extend its service life; in terms of decoration, the galvanized layer can make the metal surface more beautiful; Conductive and thermal conductivity.